Aligning the Bolt-on Butt Neck Joint

The bolt-on butt neck joint is a common and versatile system for attaching neck to body of guitars and similar instruments. The joint I most often use is similar to the original Taylor bolt-on neck joint. This joint is still used by a number of manufacturers. It is easy to implement and proven reliable. I find it to be particularly useful when building one of a kind instruments because neck-to-body alignment fixtures are not strictly necessary when using this joint. This page discusses how to fit the neck to the body, using simple sanding boards designed for this task. This article originally appeared in American Lutherie.

Initial appearance: November 14, 2021

Last updated:

July 13, 2025

Aligning the Bolt-on Butt Neck Joint

Copyright © 2016 R.M. Mottola

[This article originally appeared in American Lutherie #126.]

Post Publication Note - This article describes the same bolt-on butt neck joint fitting operation that is described in the book Building the Steel String Acoustic Guitar. Whereas the book describes the use of special sanding boards used in the fitting operation and provides templates for those sanding boards for the two example instruments discussed in the book, it does not describe how to lay out those sanding boards for any instrument. Information about layout of the sanding boards is described here.

The bolt-on butt neck joint is a common and versatile system for attaching neck to body of guitars and similar instruments. The joint I most often use is similar to the original Taylor bolt-on neck joint. This joint is still used by a number of manufacturers. It is easy to implement and proven reliable. I find it to be particularly useful when building one of a kind instruments because neck-to-body alignment fixtures are not strictly necessary when using this joint. Such fixtures are useful in even small production contexts of course, but for one of a kind instruments I like to avoid making one of a kind fixtures if I can avoid it.

The form of this joint I use most often keeps the mating surfaces of heel and body flat. Holes are drilled through the neck block for the neck attachment bolts. If the instrument features trussrod adjustment inside the body then a short channel through the top and neck block for the trussrod end is cut as well. I use two threaded inserts in the heel, of the type usually used for metal. I use these because they may hold better in wood end grain than typical inserts intended for wood (see “Testing Threaded Inserts”, American Lutherie #101, 2010, p. 54 for more on that). A 0.125” (3.18mm) deep pocket is cut into the heel end, leaving 0.25” (6.35mm) wide perimeter walls which will contact the body.

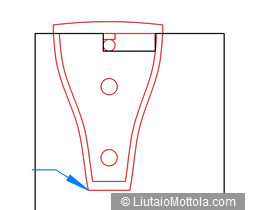

In the most basic implementation of this joint the heel is bolted to the body using two bolts and the fretboard extension is glued down to the top in the conventional fashion. In addition to this style I also use a fully removable joint. Here, the fretboard extension is also bolted on. The extension has a threaded boss attached to the bottom. This boss fits into a round pocket drilled into the top and a shelf under the top from the neck block to the upper transverse brace. Photo 1 shows both parts of this fully removable joint.

Photo 1 – The two parts of the fully removable bolt-on butt neck joint. The slot in the top provides clearance for the trussrod adjustment end. A drilled pocket in the top provides clearance for the threaded boss attached to the underside of the fretboard extension. Note the pocket routed into the contact surface of the heel. This reduces the contact area to just two walls and the heel cap. This reduction of area greatly simplifies fitting of the neck.

A guitar neck must be fitted to the body to achieve proper alignment. The body contact surface of the heel must fully contact the body. The underside of the fretboard extension must fully contact the area of the top underneath it. This requirement usually requires pitch and (possibly) roll adjustments to be made. And the centerlines of the neck and top must also be aligned, requiring yaw adjustment as well. This article explains simple tools and methods which can be used to quickly and accurately make these adjustments.

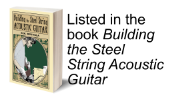

Figure 1 – Making the trussrod clearance notch in the end of the sanding board as wide as the distance from inside one of the “walls” of the heel to the other side of the trussrod (w) will provide the most sanding movement while maintaining sandpaper contact over the entire area at all times.

I will most often fit the neck when neck and body woodworking are complete but before the edges of the bindings are filleted. The first step in the process is flattening contact surfaces of the body and the heel. A sanding board is used to do both. The sanding board used to ensure the body contact area of the heel is flat is one of a pair used for the entire fitting process. Each of these starts as a 4.5” x 6” (114.3mm x 152.4mm) piece of melamine-covered particleboard. This material is very useful for jigs and fixtures because it is flat, stable and cheap. It is available in big-box home stores. It is generally used for kitchen cabinet shelves. A notch is cut in the center of each end of the board to provide clearance for the trussrod end. If the width of these notches is a bit less than the distance between the inside of one of the “walls” of the heel contact surface and the side of the trussrod farthest from that wall, then the board can be used mindlessly to flatten the body contact area of the heel. Figure 1 shows this distance. More on that in a bit.

After the trussrod clearance notches are cut out, one side of the board is covered with sandpaper. I use CAMI 80 grit Pressure Sensitive Adhesive (PSA) sandpaper on a roll for this. The paper must be carefully trimmed so it is flush with the notch ends of the board. After trimming, briskly rub a piece of scrap wood back and forth over each end of the sanding board. These precautions will prevent the edge of the sandpaper from cutting into the underside of the fretboard when the sanding board is used.

The sanding board can be held conveniently in a bench vise, sandpaper side up. To flatten the heel contact surface the neck is positioned on the sanding board as in photo 2 and scrubbed back and forth with the underside of the fretboard in contact with the notch end of the board. This will uniformly sand the entire contact surface. It doesn’t take many strokes to do this, depending of course on the wood species used for the neck and the general flatness when you start. I can often do this with only four or five strokes. You’ll know you are done when you see uniform sanding scratches on the entire surface. You can also mark up the surface with pencil before starting and scrub until all pencil marks are removed. Note that if the clearance notch for the trussrod end is sized as per above then there will always be sandpaper in contact with the surface no matter how far you scrub, because the trussrod will contact one of the walls of the notch and prevent further movement that would bring part of the contact surface over the notch itself. When both body and neck contact surfaces have been flattened they can be held together to quickly check contact. You may need to do a tiny bit of trimming right in the corner between heel and fretboard. This is quickly accomplished using a skew chisel or knife. Holding the heel approximately in place on the body will also indicate if pitch needs to be adjusted.

The pitch of the neck relative to the body is perfect if the underside of the fretboard extension fully contacts the top when the heel is fully contacting the body. This of course requires that the area of the top that will be under the extension be flat. My construction techniques generally guarantee this, but at this point in the construction process I’ll check flatness of the top in this area and flatten it with a sanding board if necessary. Of course, due to the thinness of the top only minor sanding can be done here. Pitch adjustment is almost always necessary. If the neck is pitched forward too much then only the fretboard end will contact the top. If it is pitched backward too much then the fretboard extension will be angled up, away from the top. Each of these misalignments is dealt with in its own way. Let’s look at the case of the neck pitched forward first. In this case we need to remove a wedge of material from the contact surface of the heel where the point of the wedge is at the intersection of heel and fretboard, and the fat part of the wedge is at the end of the heel. See figure 2.

Photo 2 – The leftmost image shows the sanding board used to flatten the contact surface of the heel. It is clamped in the vise and ready for use. The neck is positioned as shown in the center and right images and scrubbed back and forth to flatten the contact surface of the heel. If the clearance notch is sized correctly, contact between the trussrod and the walls of the notch will prevent the heel from moving in such a way that there would not be sandpaper in contact with the entire contact surface of the heel. This guarantees that sanding will result in a flat surface.

Removing this wedge is performed by pulling sandpaper across the contact surface. To perform this alignment operation the sanding board used to flatten the contact surface of the heel is flipped over to reveal its smooth side and clamped in the vise. A strip of 80 grit sandpaper approximately 2.75” x 8.5” (152.4mm x 215.9mm) is notched in the center of one end to provide clearance for the trussrod end. The sandpaper is positioned sandy side up on top of the board with its end aligned with one end of the board. The neck is placed on top of that with the contact surface of the heel pressed to the sandpaper. The other end of the sandpaper is grasped and the paper is pulled completely out from between board and heel while pressure is applied to the heel. This operation is repeated until an appropriately sized wedge of material is removed from the heel. This entire sequence is shown in photo 3.

Figure 2 – Exaggerated example of a neck with too much forward pitch. A wedge of material (indicated by the dashed line) must be removed from the heel to pitch align neck to body.

The reason this operation removes a wedge of material is that a different amount of sanding is done at each point along the length of the heel. There is no sanding at the very top of the heel because no sandpaper moves under this point. But a length of sandpaper equivalent to the length of the heel moves under the heel cap end of the heel, removing the maximum amount of material here.

Although it is possible to calculate the size of the wedge of material to be removed in advance I find it really isn’t necessary to do that. Since the neck needs to be positioned for each pull of the sandpaper it is just as easy to check the pitch alignment as you go. I’ll regularly switch hands for these pulls too, using one hand to press the heel down and the other to pull the sandpaper for one pull, then switch hands for the next pull. This helps to balance out unevenness in pressure on the heel, which could cause one side to wear more than the other.

Photo 3 – The sandpaper pull technique is used to remove material from the heel for pitch alignment of a neck with too much forward pitch. As the sandpaper is pulled from between heel and board it removes a wedge of material from the body contact surface of the heel.

In the case where the neck is pitched backward too much a different alignment technique and a different sanding board are needed. In this case a wedge of material also must be removed from the heel, but in this case the thick end of the wedge it at the top of the heel near the fretboard as shown in figure 3. The sanding board needed is made of the same material and is of the same dimensions as the previous one. A notch to clear the trussrod end is measured and cut on one end in the same manner. 80 grit PSA sandpaper will be attached to the board so that, when the heel is rubbed side to side over it, there is always sandpaper moving under the heel at the fretboard end, and there is never sandpaper under the other end. The middle areas are sanded in proportion to their locations along the heel. This requires two strips of sandpaper, one on each side of the sanding board surface.

Figure 3 – Exaggerated example of a neck with too much back pitch. A wedge of material (indicated by the dashed line) must be removed from the heel to pitch align neck to body.

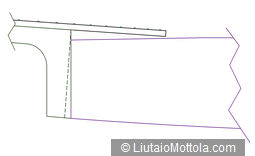

Laying out the boundaries of the sandpaper requires marking of the board surface. First, put the neck in position on the board and slide it as far as it will go to the right. Make a mark on the board at the arrow in the top image of figure 4. Now slide the neck as far as it will go to the left and mark the board at the arrow shown in the bottom image of the figure. Connect these two marks with a straight scribed line. Mark the right hand side of the board in the same fashion. The PSA sandpaper strips are applied with an edge against each of the scribed lines and then trimmed flush to top, bottom and side edges. Again, it is important to burnish the edges of the sandpaper that will contact the underside of the fretboard to remove any grit that could gouge a slot into the fretboard.

Figure 4 – Marks are made to locate the edge of the sandpaper on the left side of the sanding block used to pitch align a neck with too much back pitch.

During use, the movement of the edges of the heel over the edges of the sandpaper would quickly peel and tear the sandpaper. To prevent this, the central portion of the board’s surface is covered with some slippery material of the same thickness (or slightly thinner) as the sandpaper used. The sandpaper I use is 0.036” (0.91mm) thick. For the central covering I use 0.032” (0.81mm) PVC sheet, attached with thin double sided tape. The tape is 0.003” (0.08mm) thick, for a total thickness of 0.035” (0.89mm). Lots of other readily available materials can be used too. I have often just used file folder card stock, in as many layers as needed.

Use of this board is similar to use of the flattening board described. The heel is positioned on the board with the underside of the fretboard contacting the top edge of the board. Pressure is applied evenly to the heel as it is gently scrubbed side to side. See photo 4. Check your progress regularly by test fitting the neck to the body.

Photo 4 – Sanding board used to align pitch when the neck is pitched too far back. Scrubbing the heel side to side sands the body contact surface of the heel more at the fretboard end than at the heel cap end. This pitches the neck forward. Note that the white area at the center of the board is covered with PVC sheet stock attached with double stick tape. The surface of the PVC is just a bit lower than that of the sandpaper.

You may notice in the images above that the edges of the sandpaper strips are parallel to each other and to the sides of the board. This is because I designed the taper of the heel of the instrument shown so that it would work out this way. If you have the option to do this then it makes it easier to put the center material on the board. It also means the board is symmetrical end to end, so you can notch the other end as shown in the images and use both ends. This makes the sandpaper last longer. Plus, alternating ends when sanding a heel helps to prevent uneven pressure from wearing one side of the heel more than the other.

Following pitch adjustment and prior to yaw adjustment is the time to center the neck and make any roll adjustment necessary. This is straightforward. Measure the width of the fretboard at the body contact point and mark half of this on either side of the body centerline in pencil on the bindings. Bolt the neck on with bolts hand-tight, try to center the fretboard between the marks, and press the fretboard extension into full contact with the top. Sometimes centering can’t be done because one of the bolts is up against the side of its hole. In this case the hole is enlarged a bit, and the fit tried again. Once the fit is good, I’ll turn the instrument over and visually check to be sure the bottom of the heel is centered about the back centerline. If this is a little out it generally means that the area of the top under the fretboard extension is not quite perpendicular to the rib seam at the neck block and the neck has to be rolled a bit to get perfect contact between fretboard extension and top. This roll can sometimes be corrected with judicious use of a sanding board on the top, but of course there is not a lot of material that can be removed here at this point in construction and so you may just have to live with it.

After the neck can be bolted on so the fretboard is between the marks made on the top bindings, I will use a knife to nick the edge of the bindings right up against the sides of the fretboard. This makes those alignment marks permanent, and when I’m filleting the bindings they let me know where to stop the filleting and leave them square. I’ll also make similar marks either side of the heel cap on the back bindings, on instruments where the bottom of the heel cap will be flush with the surface of the back.

The next alignment step is yaw adjustment. Yaw is checked using a straightedge (for a guitar a 24” (609.6mm) ruler works well) and a small ruler. With the neck bolted in place the straightedge is placed in contact with one side of the fretboard and lying on top of the top. One end is aligned with the nut slot. In this configuration the straightedge is used to continue the line of the fretboard side down onto the body. The small ruler is placed on the top and against the end of the long straightedge so that the distance from the straightedge end to the top centerline can be measured. Write that measurement down and then do the same thing on the other side of the fretboard. The neck is yawing toward the side with the longest distance from straight edge end to top centerline. I will generally consider yaw adjustment to be necessary if the difference between the two measurements is greater than 0.065” (1.65mm).

To correct the yaw, material must be removed from one side of the body contact surface of the heel, the side that showed the longest distance from straight edge end to top centerline. I always pencil mark this side of the heel, because I am easily confused and if I don’t mark it I will often go ahead and remove material from the wrong side, and then wonder when I check the yaw again why it just got worse. Material is removed using yet another special purpose sanding board. Of the same dimensions as the other boards and with the same notching on both ends, this board is covered with sandpaper on one side only of its longitudinal centerline, and covered in slippery PVC or other material on the other side.

Photo 5 – The yaw adjustment sanding board has notches in both ends, sandpaper stuck to one side of the surface, and slippery plastic of the same thickness as the sandpaper on the other. In these images material is being removed from the side of the heel under the sandpaper. If material needs to be removed from the other side the neck is positioned at the other end of the board. The sanding stroke extends from where the bottom corner of the heel at one side contacts the sandpaper edge, to the bottom corner of the other side.

To use the sanding board, the heel is placed on the board so that the side from which material will be removed is over the sandpaper (photo 5). This will require use of one end of the board or the other, depending on the side of the heel from which material must be removed. The heel is positioned so that the bottom corner of the heel on the not-to-be sanded side is in contact with the edge of the sandpaper. With even pressure on the heel, the neck is scrubbed over the sandpaper until the corner on the other side of the heel is in contact with the sandpaper edge. A back and forth scrubbing in this range will remove material only from one side of the body contact surface of the heel.

As with other adjustments mentioned it is possible to calculate how much material needs to be removed in advance, but I find it quicker to just go at it and regularly check my progress.

After all adjustments are made the neck is returned to the flattening sanding board for just a few strokes to be sure the contact surface is still flat. Following this final flattening the position of the neck on the body can be checked again. It is sometimes the case that one adjustment procedure changes the alignment of a previous procedure but if this happens the discrepancy will always be small and easily reworked.

The sanding boards used to perform these adjustments are quick and easy to make and generally last a long time under normal use. The alignment procedures detailed here are quick and easy to perform and produce accurate and consistent results.